GEMINI XPROJECT

The founder of Gemini Shale Solutions, a start-up in the water collection side of the gas & oil industry, was looking for a sensor system to accurately measure the volume of water in a 325-gallon tank at various pitch and roll angles.

Our client knew he wanted us to use a guided wave radar sensor and an inclinometer to calculate the volume. With the sensors given, we still had to develop the circuits to connect them to a Raspberry Pi, create the algorithm to calculate the volume, and create a rig to test the setup. On the team of six, I primarily worked on designing the rig to angle the tank, and mounting hardware to the tank itself.

|

|---|

|

|

ANGLING RIG

After considering many options, performing some force analyses, and asking our advisors and the staff in the machine shop more than a few questions, we decided on using a square steel frame with leveling feet in the corners that allows the frame to be angled manually using wrenches. The leveling feet are also swiveling, with a maximum angle of 7° to allow the support to angle as the tank became angled.

CAD model of the tank rig |

|---|

CAD model of the tank on the frame |

The frame before the tank was attached |

The tank on the frame |

The tank angled on the frame |

MANWAY CAP

The guided wave radar head did not fit into the cap that came with the tank, so I designed and made a two-part cap assembly that fits into the tank’s manway, has mounting holes for the guided wave radar head, has an access hole for the hose used to fill the tank with water, and serves as the mount for the electronics and user-interface screen.

The final CAD design for the cap |

|---|

The first iteration of the cap |

The final version of the cap, with the guided wave radar mounted |

The cap has two guided wave radar mounts so we could test its accuracy at different locations along the tank’s centerline, as other tanks this sensor setup might be used in could have manways at different points.

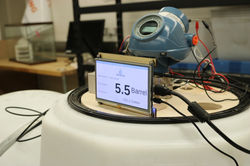

I also created a quick mount for the user interface screen, for demonstrating purposes, that mounted to the top of the tank cap.

The CAD model of the screen mount |

|---|

The screen mounted for a test |

|